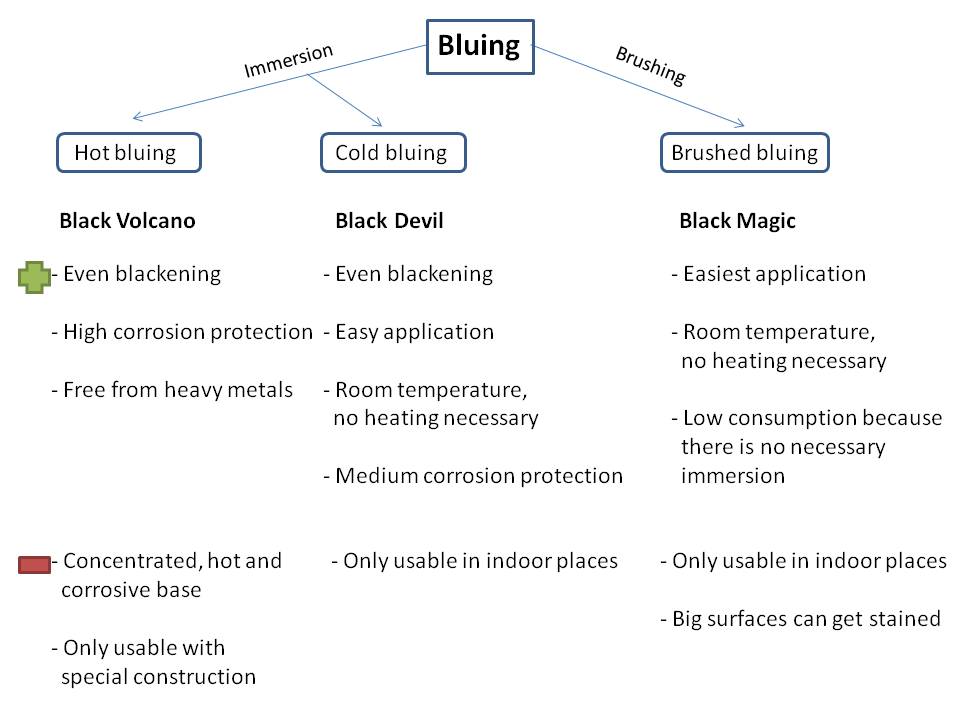

A distinction is made between immersion / tank bluing and brushed bluing. The immersion bluings are distinguished between hot and cold bluing. In the following you can see an overview of the advantages and disadvantages of the different methods.

Overview of bluing methods

1. Immersion bluing process – cold process

The Tifoo immersion bluing Black Devil is an easy to use cold bluing system consisting of 4 components.

- The bluing is done at room temperature and for that possible in almost any places

- The bluing doesn’t change the measurements of the blackened objects

- The blackening is achieved by a chemical conversion on a derusted metal surface

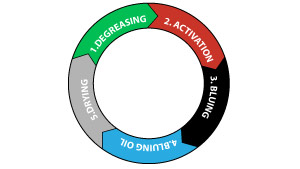

- Degreasing, activating and bluing are the necessary steps.

- The lasting corrosion protection is achieved by immersion into Tifoo Dehydration Oil.

The process takes place in different, easy immersion steps into different baths (watch the opposite animation)

Cold bluing process

2. Immersion bluing process – hot bluing

The hot bluing is also an immersion process and differs from the cold bluing in its composition and the fact that the bath has to be heated. The problem here is that you have to work with hot base, which means that there will be high energy costs and special equipment and ventilation systems will be needed. These are disadvantages that are absent in cold bluing processes. It is generally advisable to have the hot bluing done by specialists.

3. Brushed bluing

The Tifoo Black Magic fast bluing is applied with a brush. The surfaces can easily be painted with it and the result of a pitch-black bluing layer will be achieved immediately. This allows you to easily repair damaged parts (e.g. for gun refinishing).

4. Patination

Patination means the process of natural or artificial aging of metals like copper or silver. The Tifoo Silver patination for example blackens silver surfaces and the Tifoo Patination is suitable for dyeing and blackening of non-ferrous heavy metal like copper or brass. You can also use these products to get an antique look for your products.